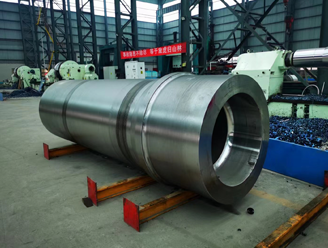

Often known as “impression die forging”, closed die forging involves two or more dies containing impressions brought together. This simple process displays great versatility. Manufacturers can create a nearly limitless array of shapes and complex metal parts in this way.

Closed die forging under controlled conditions permits the creation of forgings of all sizes within relatively tight tolerances. However, manufacturers usually employ this process to produce small, intricately shaped and patterned components in high volumes.

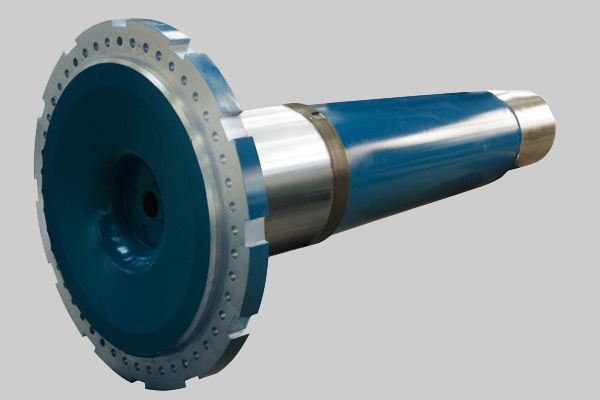

Custom die forgings play an important role in several important economic sectors, including the aerospace, automotive, manufacturing, electronic, semiconductor, construction, and food processing industries.

CREATING CUSTOM CLOSED DIE FORGINGS

The process of custom closed die forgings utilizes two or more metal dies. During this forging process, the manufacturer to some extent reproduces and automates the action of a blacksmith striking hot metal on an anvil to change the shape of a metal part.

THE FORGING PROCESS

With the assistance of a machine, a manufacturer programs the upper die to strike a heated metal billet placed on the lower die. This process may rely on a variety of different forging methods.